Exentec delivers high-purity gas supply systems—from single components to turnkey solutions—tailored for labs and production environments. Options range from fully automatic to manual gas cabinets, with integrated safety, monitoring, and high-purity distribution for maximum reliability and compliance.

Our company’s own manufacturing capacities allow us to manufacture complex systems quickly and flexibly, even under clean room conditions. When assembling under clean room conditions or manufacturing custom-fit equipment, our expertise in welding technology, process control & automation technology and testing & quality control are seamlessly intertwined.

High Purity Bulk Gas Systems

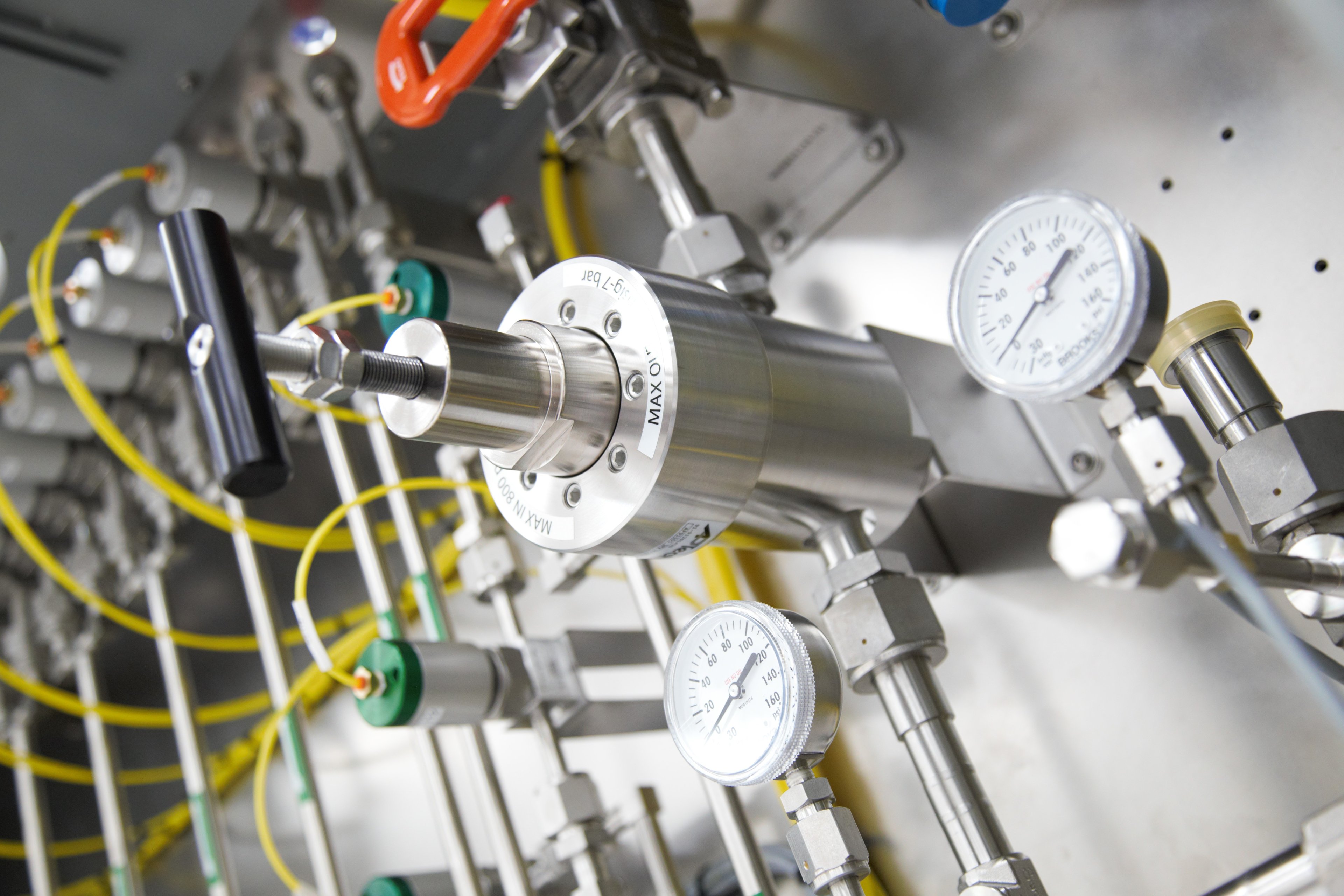

Exentec’s High Purity Bulk Gas Systems offer turnkey or specialized solutions for safe, efficient gas delivery across industries like semiconductor manufacturing. From pipeline controls to purification skids, systems are fully customizable for diverse gas types—maximizing safety, productivity, and lifecycle value.

High Purity Spec Gas Systems

Exentec’s High Purity Spec Gas Systems feature fully integrated PLC/HMI control with remote access and automated pressure regulation for precise, uninterrupted gas flow. Designed for compact cabinets, they reduce manual intervention by 30%, minimize pressure fluctuations, and enhance safety through full automation.

Gas Cabinets

Exentec’s gas cabinets offer flexible configurations and 99.999% uptime, with both standard and custom solutions tailored to specific applications. Options include manual to fully automated control, 1–3 cylinder setups, and integrated purge/process panels—all designed for safety, reliability, and easy operation.

Gas Blender Systems

Exentec’s Gas Blender Systems provide precise, automated gas mixing up to 250 slpm, with real-time monitoring and ±0.3% accuracy. Equipped with PLC control, built-in analyzer, and safety features in a compact, SEMI-F14-compliant enclosure, it ensures reliable performance for demanding applications.

Valve Manifold Boxes

Exentec’s Valve Manifold Box (VMB) enables safe, reliable gas distribution with up to 8 sticks, featuring manual to fully automatic control and optional N₂ purge and vacuum for maintenance. Available in panel or exhaust cabinet designs, VMBs offer advanced safety features, double isolation, and customizable accessories for inert or hazardous gas applications.

Valve Manifold Panels

Exentec’s high-purity media supply team delivers innovative and reliable gas panels backed by extensive manufacturing and installation experience. Panel options include automatic, manual, modular, and purge configurations—such as Auto-Crossover Panels that ensure uninterrupted gas flow by switching cylinders automatically when one is depleted.

Bulk Specialty Gas Systems

Exentec’s Bulk Specialty Gas System (BSGS) delivers safe, high-flow gas supply with PLC automation, dual-source capability, and a user-friendly touchscreen interface. Built in a robust, SEMI-F14-compliant enclosure, the system supports advanced safety features, precise control, and optional accessories for flexible, high-purity gas delivery.

Liquide Precursor Delivery Systems

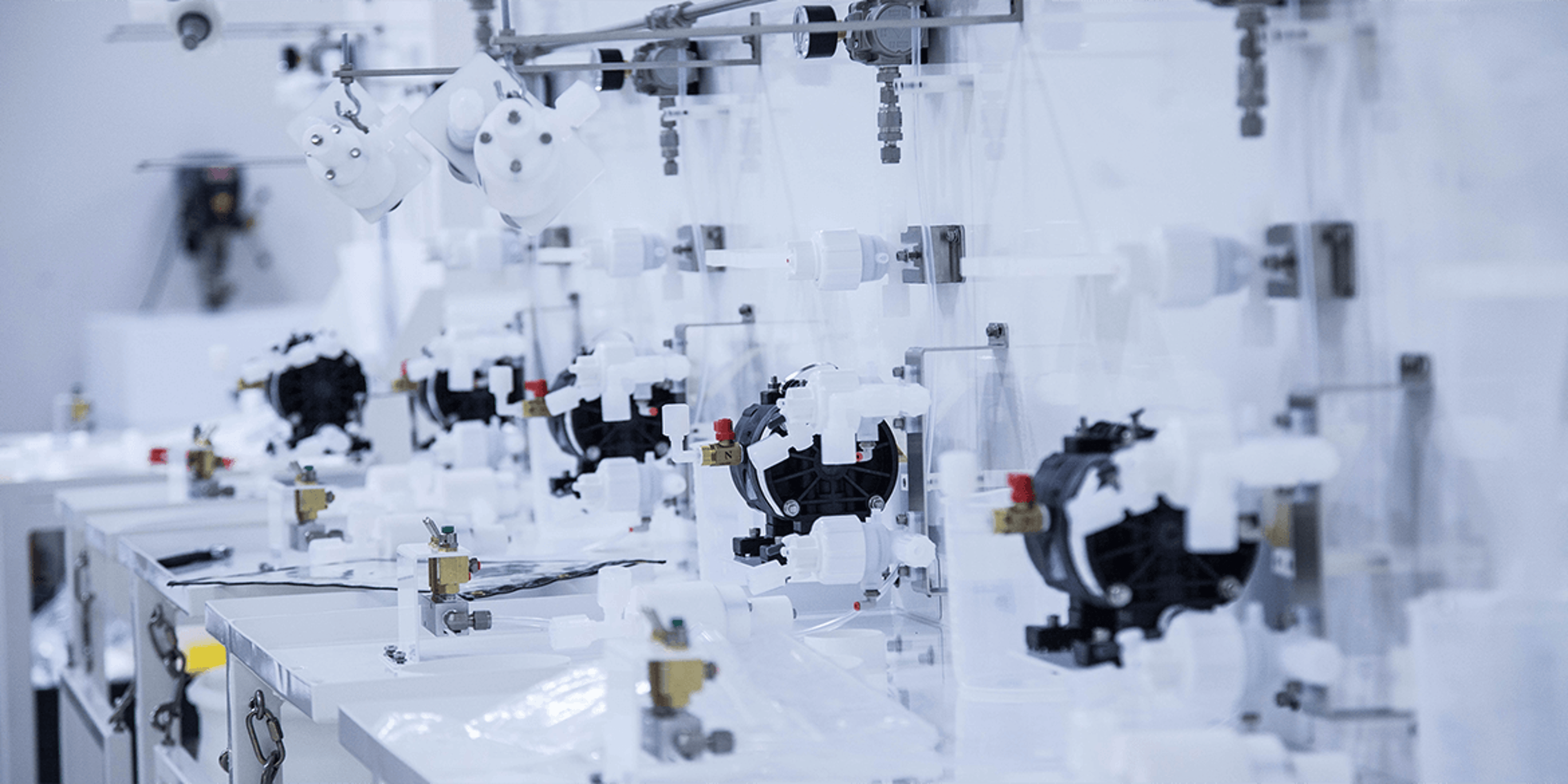

Exentec’s Liquide (precursor) Delivery System is a chemical distribution system designed to maximize efficiency and performance. The stand-alone system includes redundant panels with auto-crossover capability for increased uptime > 99.9%. The small footprint with large process capacity is designed to distribute liquid chemical via a push gas.

Gas Delivery System Controllers

Exentec offers a versatile range of gas delivery system controllers, customizable to specific gas types, purge routines, and control platforms. Options include manual to fully automated VMB controllers (4- or 8-stick) with Allen-Bradley or Siemens PLCs, as well as custom and direct replacement models like the AVMB4S and AVMB8S for legacy system upgrades.

Vapor Delivery System

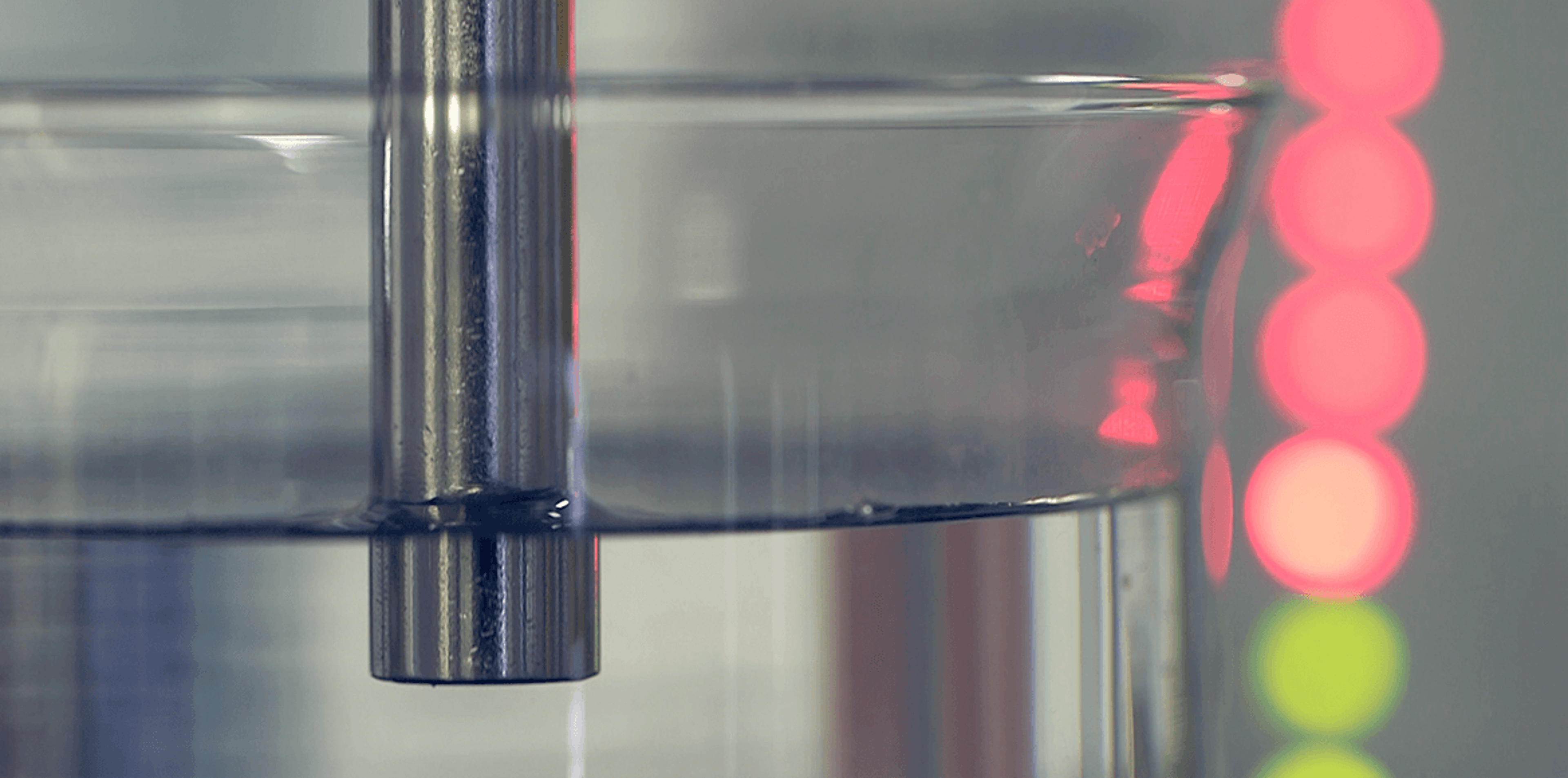

Exentec’s Vapor Delivery System is a compact, high-purity solution for precise chemical vapor distribution in advanced manufacturing applications. Featuring a stainless steel bubbler, optional chiller, and smart control in a durable enclosure, it ensures consistent vapor flow, flexible integration, and enhanced safety for processes like ALD, CVD, and epitaxy.

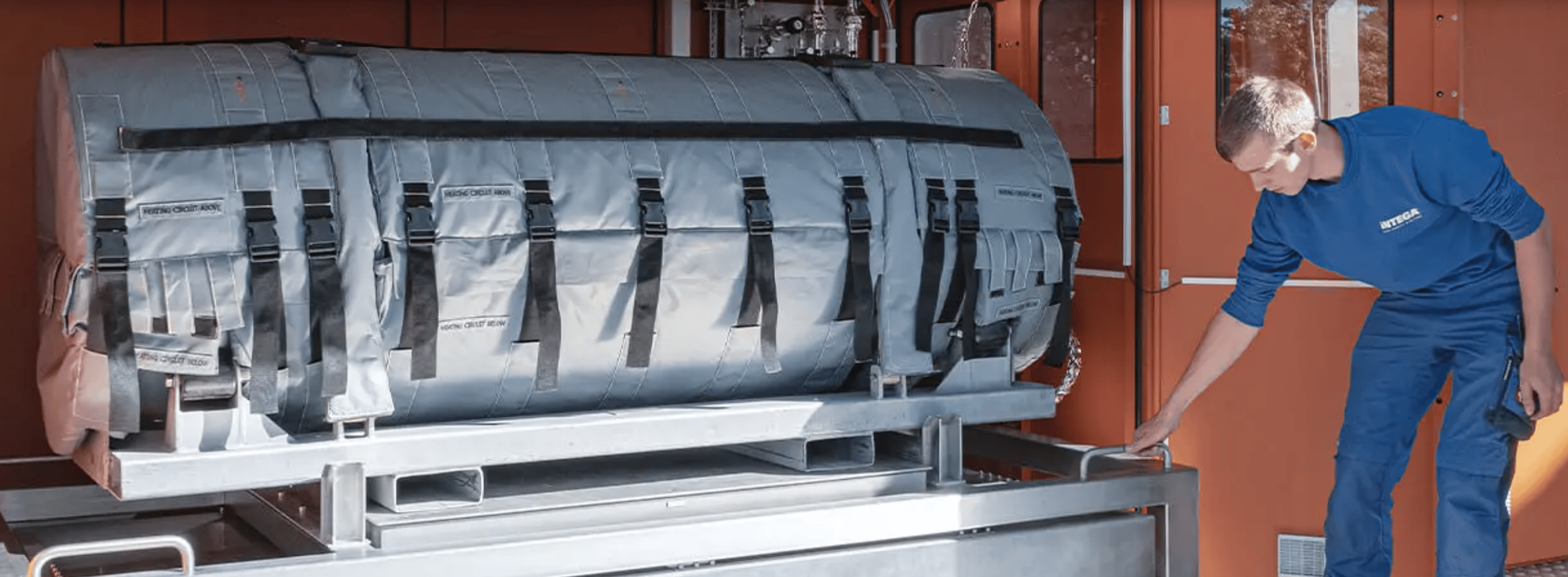

Customized Gas Supply Container

Exentec’s “Plug & Process” gas supply containers are modular, prefabricated systems designed for rapid, cost-effective deployment of ultra-high-purity gas infrastructure. Fully customizable and automated, they feature integrated safety, ventilation, and control systems—delivering space-efficient, scalable solutions with expert long-term support.

Installations & Machine Connections

Our in-house CAD department develops and designs components and we manufacture them at our specialized production sites. Our experts process stainless steel tubes in a wide range of qualities using orbital or manual welding processes. We use joining techniques including:

- VCR Technology

- Pipe fitting

- Flange technology

- Press fitting systems

- Plastics processing (welding, gluing)

Cleanroom

Superior solutions and comprehensive services

We develop, produce and maintain reliable cleanroom products and production environments for ultra-clean controlled atmospheres.

Mini Environments

In the battery market, Exentec pioneers a unique modular Mini Environment concept, integrating energy reduction and technological improvements.

Air Handling Units

Air Handling Units from Exentec are distinguished by energy-efficient design. Our research and development team works with state-of-the art equipment and always contributes the latest knowledge.

Critical Subsystems & Controlled Environments

Pure media supply systems for sensitive products

Chemical Supply

Ultra-high purity chemical & slurry blending and distribution systems

Ultra-high purity chemical & slurry blending and distribution systems

Ampoules and Sensors

We manufacture liquid level sensors, pyrophoric chemical handling and DOT 4B ampoules, cylinders and canisters widely used in the semiconductor, photovoltaic and battery industries.

Process Exhaust

We set the industry standard for safe and reliable corrosive fume exhaust duct systems