In-line Blending

In-line Blending

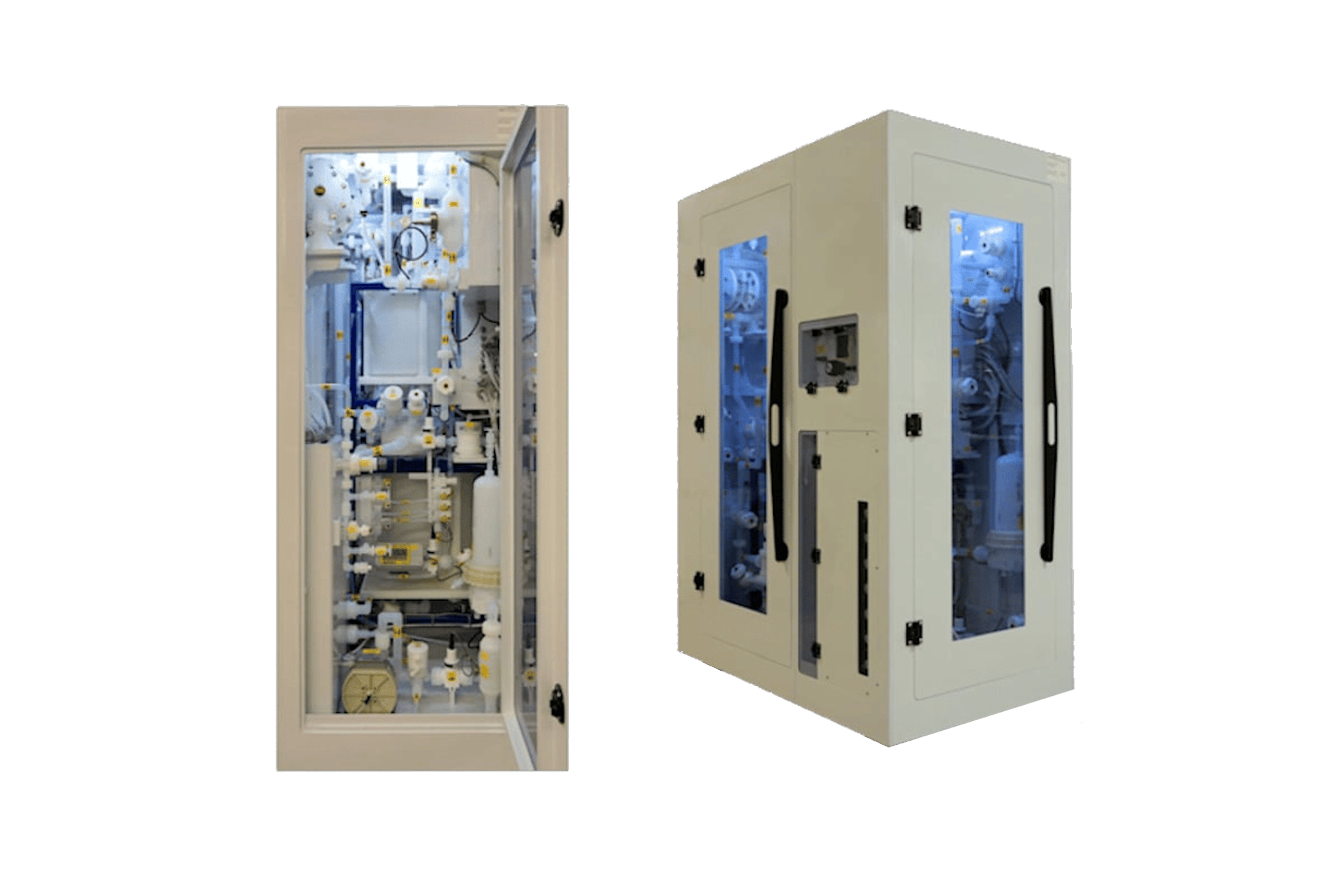

Exentec’s patented On-Demand In-Line Chemical Blending and Supply of Chemical Solutions technology can accommodate on-demand dynamic change in flow rates

Exentec’s patented On-Demand In-Line Chemical Blending and Supply of Chemical Solutions technology can accommodate on-demand dynamic change in flow rates by the end users or points of use while maintaining precise blend accuracy. Embodiments of the blending system can produce mixtures and supply them to multiple end users or points of use at variable on-demand or changing production rates while maintaining a high-resolution blend accuracy at independent control points. The blending system can correct a blended product that may have been temporarily stored in a tank, vessel, or supply line prior to delivery to, or on route to the end user, or to single or multiple points of use.

The blending system can have an ability to track and confirm the chemical compositions of the initial system's entering chemical components, the associated intermediate blends, and the various final mixture blends while the system's output production rate varies. The blending system can define each incoming material's composition with in-line metrology and feed this information forward for blend control.

A continuous or in-line blending system can eliminate the large batch preparation and holding tanks, which leads to a small system volume, more product compounding flexibility, faster product formulation and turnaround, and a substantially lower capital cost. Continuous and in-line blending can reduce waste, cleanup time, and effluent volumes.

This is just another example of how Exentec is pushing the envelope toward more efficient and sustainable semiconductor production technology.

High Purity Chemical Systems

We offer equipment, field support service and technical expertise to meet various application needs of high purity fluid delivery, chemical blending and state-of-the-art CMP slurry systems for semiconductor manufacturing and other high-tech industries.