Virtual Design

Virtual Design

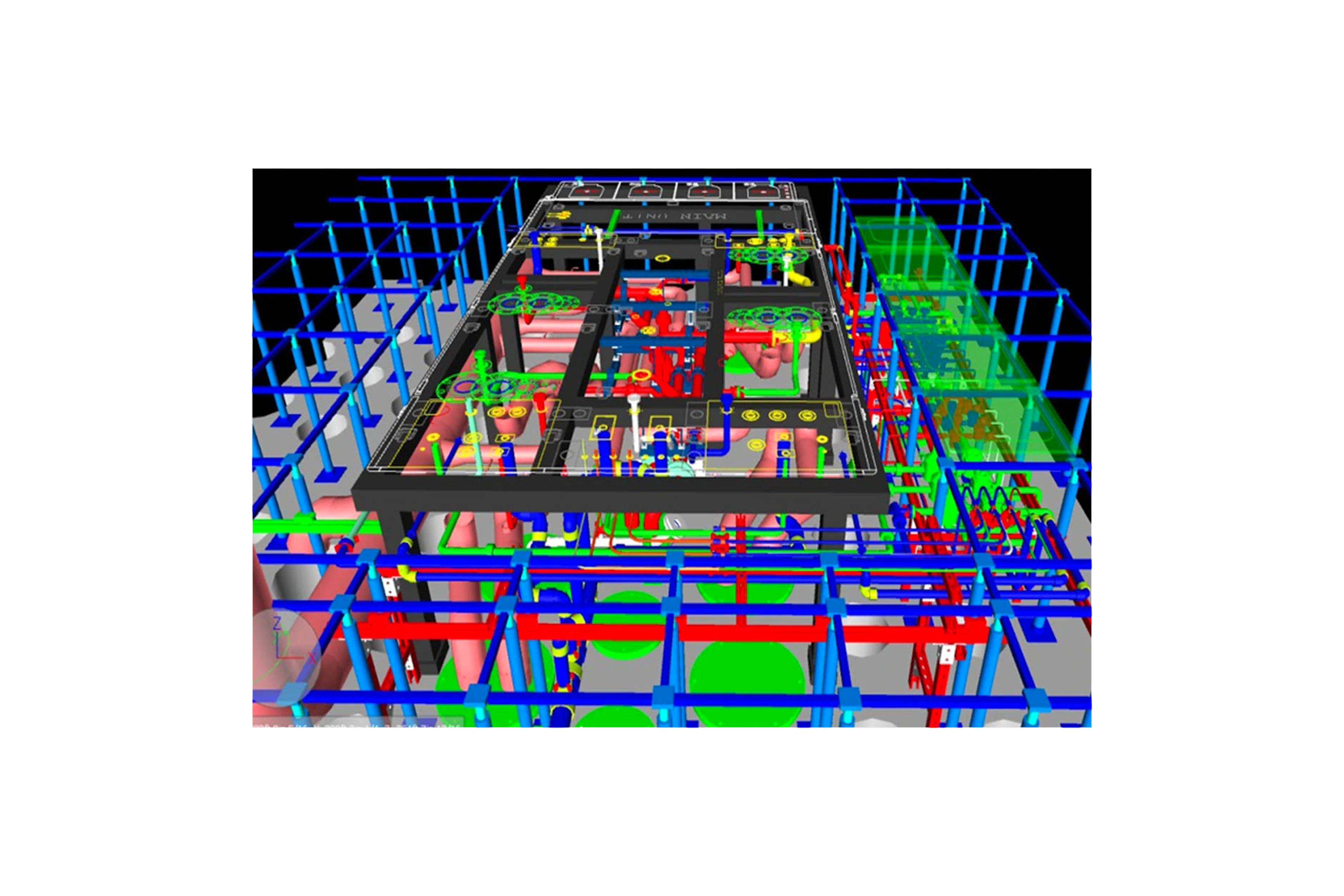

Our VDC process improves productivity and reduces rework

One major benefit of BIM (Building Information Modeling) is increased coordination between all trades, which reduces typical conflicts, change orders and “requests for information” during construction, giving our clients the greatest value possible for their construction dollar.

Our VDC team can:

- Digitally design and build systems in a virtual model, where it can be prefabricated and installed safely with higher productivity

- Make full use of the BIM process to assist our field teams

- Create and implement digitally collaborative workflows to improve communication and productivity

In existing facilities, we utilize 3D scanning technology throughout the BIM process to accurately capture the as-built environment. New design models are placed within the scans to confirm fitment, placement, and routings with client prior to prefabrication and installation.

Prefabricating Systems

- With a coordinated, constructible model, many of our customers’ systems can be prefabricated in our shops located nationwide

- We use our model files to drive our automated CNC pipe bending machine

- It’s a digital world, and at Exentec we align ourselves with digital construction standards that increase productivity

- On successful pre-fabricated projects, increased safety and quality can be expected, as well as reduction in project schedule and cost

Process Piping

We install high-end process piping systems for advanced technology companies.

Tool Hook-up

We understand the criticality of schedule for tool hook-up and work to complete on time every time.