Design for Manufacturing and Assembly

Design for Manufacturing and Assembly

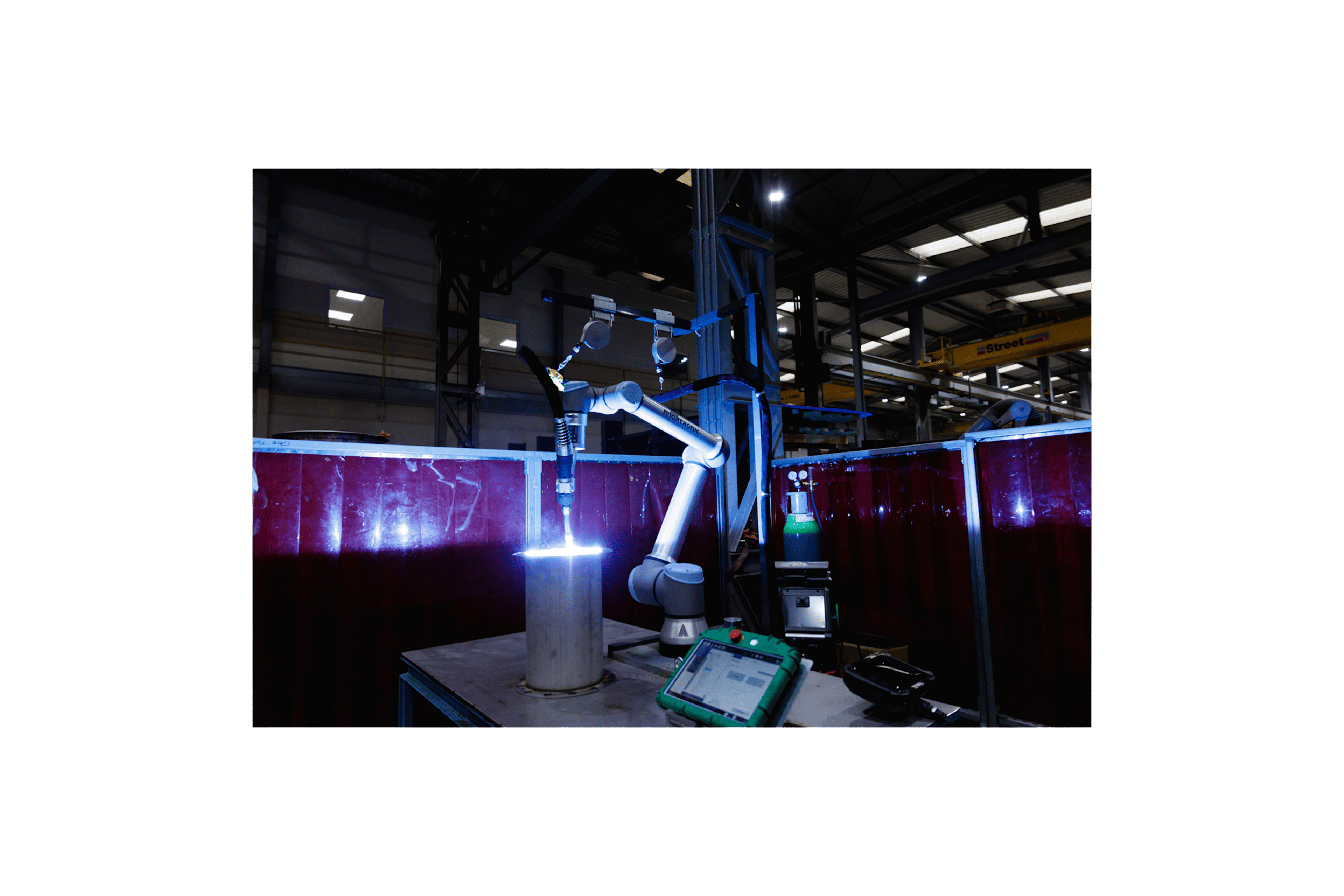

Our Manufacturing facility in the heart of Greater Manchester is purpose-built and scalable for DfMA (Design for Manufacturing & Assembly), Off-site Manufacturing and Modularization projects. By pre-fabricating assets and systems, we can reduce both time on site and installation times. Our DfMA capability ensures design, engineering, manufacturing and site teams are collaborating to maximise project efficiency

Benefits of DfMA

Exentec Hargreaves simplifies programme management by assembling multiple items into modules. This is both more cost effective and contributes to improved productivity out on site. All modular assemblies are manufactured in controlled factory conditions which allow careful management of quality, efficiency and overall project productivity. Our specialist assembly and welding teams work to approved procedures, with pre-tested modules reducing the need for further site testing and commissioning.

Reducing Waste and Emissions

DfMA means that Exentec Hargreaves can deliver projects more sustainably in order to reduce our carbon footprint and support the UK’s drive to net zero. DfMA allows for reduced waste by improving the accuracy of our products, improving material control and handling in the factory and reducing damage / reworks. We can also have a positive impact on emissions. Reduced on site labour means fewer journeys to site are required – lowering overall transport costs.

Built in Bury, Delivered on time

All ductwork systems made in our factory are packed and/or braced to prevent damage in transit and storage in accordance with BS 1133. Open ends will be blanked off in a robust manner to prevent ingress of foreign matter during manufacture, transport, storage and installation (all to TR/19, PDI Level 2). Exentec Hargreaves will provide safe and secure storage of manufactured items in line with contractual agreements. All requirements for site deliveries will be adhered to according to contract specifications.