DRYOON®

DRYOON®

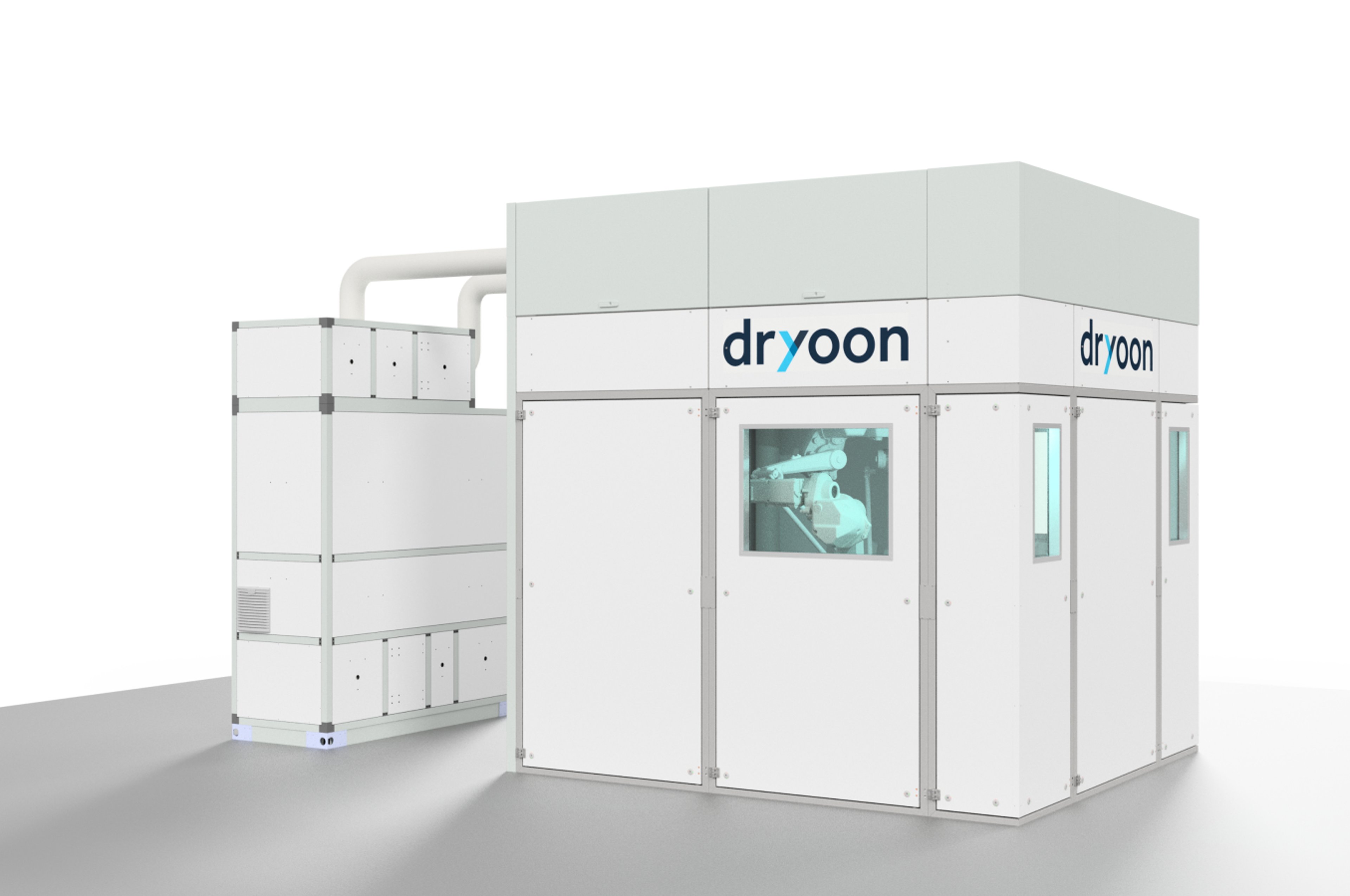

Mini Environments - Dry air exclusively at the point of use central to success

Battery cell development and production both require a total dry environment which needs to be strictly monitored and controlled. Aspects such as humidity and air flow must be guided and controlled as they can impact the quality and reliability of the battery cells produced. Mini environments reduce the required amount of dry air to a minimum, can separate the most energy-consuming steps of the battery-production, keeping them in isolated small and therefore easier to regulate environments. Added to this there is one big additional topic, occurring in all existing battery productions and challenged to control

One of the biggest risks to maintaining the required dry room environment is the presence of humans working inside it. Humans, being warm and moist objects, constantly disturb the ideal climate as they move through these large areas. Exentec focused primarily on addressing these disturbances in the development of Mini Environments, as it is critical for maintaining the required amount of dry air / the required dew point.

In short, the key benefits of Microenvironments are: Protect the product from environmental influences, create an environment with permanently controlled ideal process conditions (e.g. dew point -60°C), therefore save significant energy consumption and lastly monetary production costs.