Industry Expertise

We serve the Semiconductor, Life Sciences and Science & Research industries offering integration and installation of everything from high-purity piping to gas and chemical systems, ultra-high purity water systems, tools and equipment to clean utilities and electrical services. We will find the most economical solution to meet budget, schedule, and performance targets for projects that require renovation, expansion or turnkey construction of new facilities. As your specialty process piping and wet mechanical contractor, we can provide a full spectrum of MEP and facility construction services with deep expertise across all engineering disciplines.

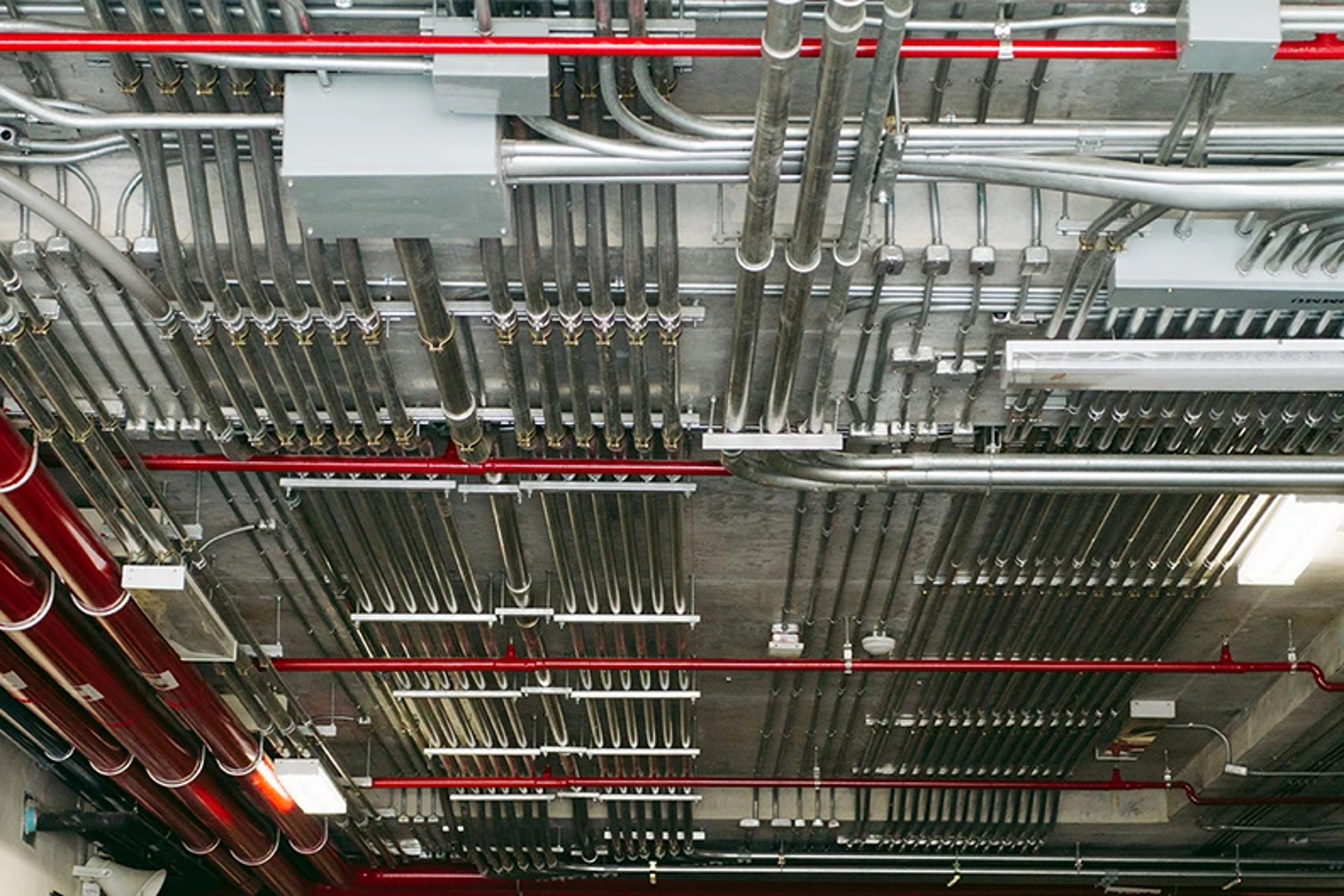

- Installing complex piping and electrical systems for high-tech customers

- Providing value with our unique perspective and methods to the most complex projects

- Improving and inventing better ways to deliver projects on time and under budget

- Seeking to build lasting relationships with every client

Process Piping

Integrated Process Systems for Semiconductor and Life Science facilities. Exentec personnel are qualified and trained in: safety, quality, orbital welding, ASME standards, BPE standards, SEMI standards, sloped piping, hygienic piping, and cleanroom protocol. We fabricate and install piping systems for ultra-high-purity piping and critical hygienic piping.

Mechanical

Exentec has a strong track record of completing projects on time and safely, delivering to our clients the process and mechanical systems they need for their processes and cleanroom environments.

Electrical

Industry-Leading Commercial Electrical Contractor. Services include plant renovation: dismantling, relocation and re-installation of equipment and facilities, electrical equipment including motors, A/C and D/C drives, instrumentation installation, wiring and calibration, and standby generator systems.

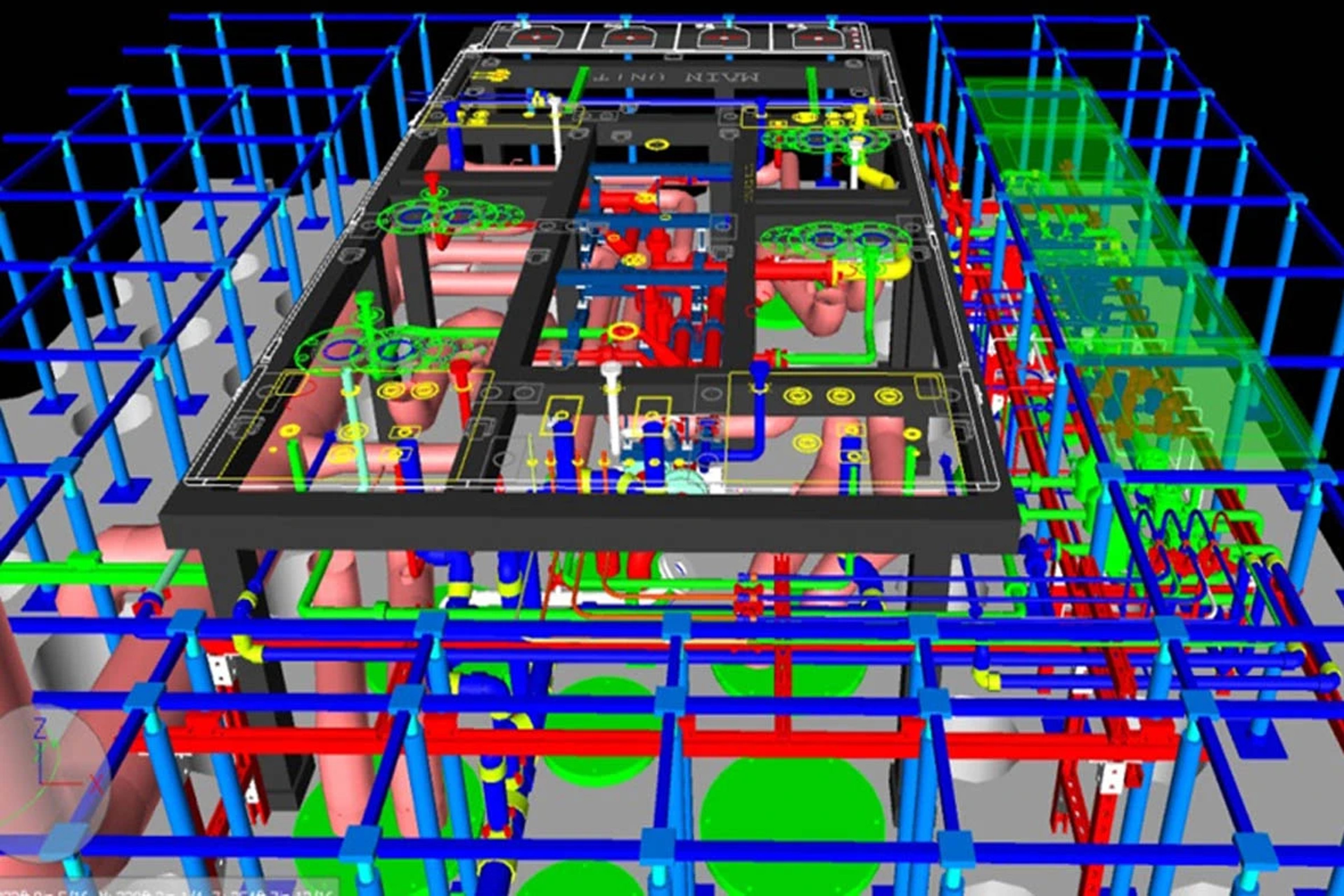

Virtual Design

Process Improves Productivity and Reduces Rework. One major benefit of BIM is increased coordination between all trades, which reduces typical conflicts, change orders and “requests for information” during construction, giving our clients the greatest value possible for their construction dollar.

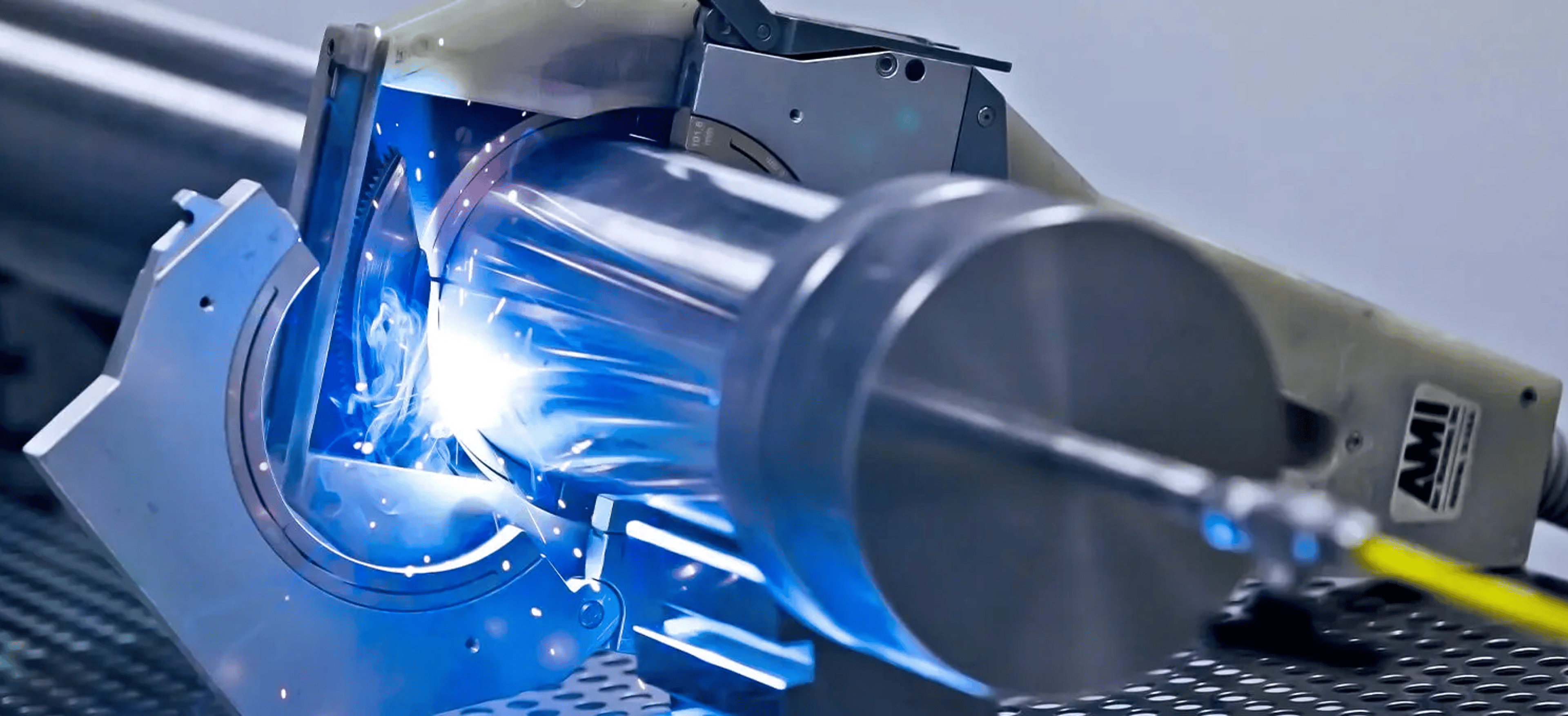

Welding Technology

Using the modern TIG process, we meet the highest demands for precision and purity. With orbital machines with closed welding heads, we can process pipe diameters from 3 to 152 mm and wall thicknesses up to 3 mm. The primary materials are corrosion-free, austenitic stainless-steel and nickel-based materials.